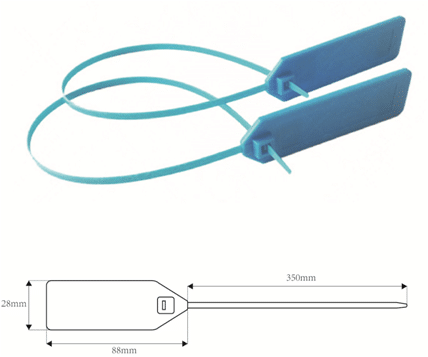

RFID Cable Tie

What’s is RFID Cable Tie?

The nylon cable ties together with ABS coat are equipped with an RFID transponder with numerous advantages for assets tracking, sourcing, management. even for smart identification by a long distance.

,![]() ,

,![]()

1/ ABS Cable

RFID Cable seals are resistance to chemical attack, heatproof, has a certain degree of hardness.

![]()

2/ Nylon Tie

Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides. Acid proof, corrosion resistance, good insulation, light weight, safe and non-toxic, resilience.

![]()

3/ One time use lock

It is specially designed for the problem of easy disassembly of lock in the market, one time use lock.

,

ID Tag Cable Ties

,

What’s kind of frequency you can use for RFID Cable Tag plastic?

LF: TK4100

Operating frequency 100-150 KHz, typical frequency: 125KHz

Reading distance is about 0-8cm

Coil antenna prefer, which is more stable and longer reading distance than inlay.

HF: Fudan 1K, Ntag213 / Ntag215/Ntag216

Standard: ISO/IEC 14443

Operating frequency of 13.56 MHz

Fast read command

True anti-collision

Reading distance is about 0-5cm

Coil antenna prefer, which is more stable and longer reading distance than inlay.

Fudan 1K

>>1024*8bit EEPROM memory

>> Data retention time of 10 years

>> Write endurance 100.000 cycles

Ntag213/Ntag215/Ntag216 NFC function supported

>> 7-byte serial number

>> 50 pF input capacitance

>> 180, 540 or 924 bytes organized in 45, 135 or 231 pages with 4 bytes per page

>> 144, 504 or 888 bytes freely available user Read/Write area (36, 126 or 222 pages)

>> Data retention time of 10 years

>> Write endurance 100.000 cycles

UHF: Alien H3

>> Standard: ISO/IEC 18000-6C

>> Operation frequency: 860-960 MHz

>> 800-Bits of Nonvolatile Memory

>> 96-EPC Bits, extensible to 496 Bits

>> 512 User Bits

>> 64 Bit Unique TID

>> 32 Bit Access and Kill Passwords

>> Reading distance: 1-3m

![]() ,

,![]() ,

,

Why use RFID zip tie?

Cable ties are used everywhere in industrial applications, ZBTECH has added an RFID sensor make them smarter.

RFID cable tie provides an innovative solution for product identification and management in rapid and clear ways.

It’s faster to get the data, and it’s an identification carrier, also can be laser with your logo and UID number.

Unlike a barcode you don’t need a direct line of sight to read an RFID cable tie. Even put inside a bottle or box, it’s a piece of cake to read out the unique ID number.

Another issue I am sure you are familiar with in your industrial applications…

The bar code on the cable tag fade in the sunlight, get rubbed off, or damaged physically. However, this is not a problem with the RFID cable tie tag. RFID Cable Tie help you find the goods without open bags, containers, boxes in seconds, keeping the record in a safety way.

RFID-enabled cable tie makes them really adaptable for all kinds of inventory and resource tracking applications.

Applications:

1, Tie to the luggage to identify the belongings.

For some clothes wholesale, they use RFID cable tag to track the resources, where and when those clothes be purchased. If there any problems or shortage, they can know clearly, also manage the stock. In fact, wholesale put the RFID cable tag in the bulk of clothes, like 50pcs, they can get the general quantity in stock, and plan the next purchase once the quantity slow down.

2, Used for waste management

Put an UHF RFID cable on the garbage bin, encode the type of the garbage, the time of cleaning, which can help manage the waste and monitor the cleaners.

3, Manage special shape asset

Like pipe, it’s not easy to stick RFID labels, it’s can easy been tear off, some even drop off in moisture weather. Use the RFID cable tie, easy to make it.

4, RFID shoe tags

RFID cable tie attach on each pair of shoes, used for warehouse management, items tracking and tracing.

,

Process of RFID Cable Tie

- Purchase the IC

- Chip-On-Board (QC)

- Make antenna

- Combine chip with antenna (QC)

- Injection molding for ABS & Nylon tie

- Sticker the RFID transponder in the ABS coat

- Ultrasonic into the whole product (QC)

- Laser for UID number or QR code / bar code (QC)

- Testing: Strain relief Test, Chip Reading Test, Bending Test

FAQ

- Production Time?

- 7-15 working days according to the Quantity

- Sample available?

- Yes, 3-5pcs samples for free

- Matching RFID Reader available?

- Yes, fixed & handhold

- Custom color available?

- Yes, but we suggest more than 10000pcs

- Custom logo?

- Yes, Screen logo, laser logo, QR code, bar code, UID number