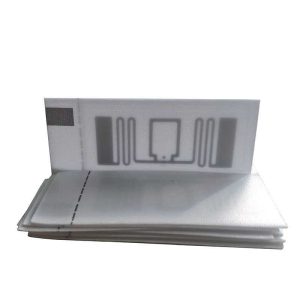

RFID Laundry tag

RFID for Laundry: How it works? What the benefits?

RFID Laundry System: How does it work?

- 1. Register clothing information. First need to prepare for the code, you need to determine or collect relevant information, such as number, name, category, department, personnel, etc., are coded information.

- 2.Attached RFID laundry tag. Write the registered laundry information into the chip of the RFID laundry tag. And attached it on the clothes.

- 3.Garment delivery. Clothing and RFID laundry tag has been bound. Use RFID reader or scan gun to make inventory. Generate report. Distribute the clothes to relevant personnel for use.

- 4.Dirty clothes are sorted and stored. When the clothes become dirty, the fixed RFID reader or scanning gun will read the RFID tags on the clothes. RFID management system will automatically record the relevant data. And print the voucher.

- 5.Clean clothes are classified and out of storage. After the clothes are washed and dried, they are sorted by laundry RFID TAG. Then out of storage shipped to the appropriate use of the department.

What can RFID technology do for laundries?

Improve laundry efficiency

Predicting the life of cloths

Optimize fabric inventory management

Automatic generation of statistical reports

RFID Laundry Tags By Frequency

13.56MHz RFID Laundry Tags

13.56 MHz HF RFID laundry tags are embedded or attached to sheets, towels and primary care scrubs or uniforms and are designed with PPS + epoxy resin to withstand over 200 cycles of duress and high temperature washing. We offer ISO 15693 and 14443 NFC memory chips.

UHF 915MHz RFID Laundry Tags

UHF RFID laundry tags with group reading capability are commonly used in industrial laundry operations, hotel fabrics and medical uniforms. These tags are flexible, can withstand high temperatures, and can withstand more than 200 wash cycles.

Which RFID Laundry tags can be used for laundry insustry ?

PPS RFID Laundry Tags

RFID silicone laundry tags

RFID Polyester Laundry Tags

Frequently Asked Questions

What is RFID laundry tag ?

Washable RFID tags, also known as RFID laundry tags, have become increasingly popular in recent years due to their ability to withstand harsh conditions and multiple wash cycles without affecting their performance. These tags are made from durable materials, such as PVC, PPS, epoxy, ABS, double layer laminated polyimide film, polyester, and cotton, which are resistant to water and chemicals.

LaundryRFID tags come in three different frequencies: 125 kHz LF, 13.56 MHz HF, and Gen 2 UHF. They are capable of supporting a range of protocols, including ISO/IEC 18000-6C (EPC Gen 2), and are ideal for use in hotels and institutions. These tags can be used to track the location and status of laundry items, such as linens, clothing, and workwear.

Manufacturers of RFID laundry tags should ensure that their products can withstand the most demanding conditions, such as high-pressure water extractors, high temperatures, and repeated washing and drying. The HLT laundry tag is one of the most advanced UHF tags on the market, with an integrated antenna and chip. It can be activated from a reader antenna anywhere in a range of RF fields, resulting in a powerful amplifier.

The UHF SiliconeRFID Laundry Tag is another popular option for industrial laundry applications. This tag is designed to withstand more than 300 wash and dry cycles and can be used for washing, drying, dry cleaning, and ironing. Additionally, the HLB PPS buttonRFID laundry tag uses a double injection molding process to ensure durability and longevity.

RFID tags have become the future of tracking and are used in a range of industries, including factories, stores, and even for tracking pets and people’s movements. These tags are also waterproof, making them ideal for tracking objects that are exposed to wet conditions, such as swimming pool equipment and boats.

As the demand for RFID fabric grows, more applications are taking advantage of this technology. For example, RFID prelams manufactured by DTBRFID meet specific layout standards and are used for logistics, asset management, and other applications. The DTB HF inlay is known for its durability and fit-for-purpose design, making it ideal for various uses.

In conclusion, washable RFID tags have revolutionized the laundry industry by allowing institutions and businesses to track and manage laundry items more efficiently. These tags are made from durable materials, resistant to water and chemicals, and can withstand the most demanding conditions. As the demand for RFID fabric grows, more applications are taking advantage of this technology, making RFID tags the future of tracking.

RFID laundry tag can be washed?

Typically, RFID Laundry Tags are utilized in industrial laundry operations, hotel linens, and medical uniforms. Flexible and able to withstand high temperatures, these Tags are made to withstand 200+ washing cycles.

Can you use RFID tag for clothes?

Yes. Several companies manufacture RFID tags encased in plastic. These labels are intended for use within the laundry and uniform rental industries. Typically, 13.56MHz tags with a read range of less than 3 feet are employed (1 meter)

How do RFID laundry tags work on clothes?

RFID tags consist of a microchip and a tiny antenna for transmitting information from the chip to a reader. When the antenna is within range, the reader is activated, and the data can be used to trigger an event in retail, such as ringing up a purchase or ordering more inventory.

Does RFID work in water?

As with all radio technologies, RFlD cannot function in the presence of water. In the presence of dissolved salts or other substances, however, water becomes a partial conductor.

Which clothing manufacturers use RFID tags?

I recently read that a number of businesses have adopted RFID as a means of inventory control. TargetTGT+0.4%, Macy’s M-1.5%, Zara, H&M, Uniqlo, Nike NKE +3.6%, Adidas, Footlocker, Lululemon, Levi’s, Ralph Lauren, Tommy Hilfiger, and Victoria’s Secret are among the market leaders.

Can RFID tags be washed?

Yes, RFID tags can be washed if they are designed to be washable. There are special RFID tags for laundry that are made with materials that can withstand the washing and drying process without being damaged. These washable RFID tags are resistant to water, chemicals, and high temperatures, making them ideal for tracking and managing laundry items in environments such as hospitals, hotels, and industrial laundries.

There are different types of washable RFID tags available in the market, including LF (125 kHz), HF (13.56 MHz), and UHF (Gen 2) frequency tags. These tags comply with industry standards such as EM 4100 and ISO/IEC 18000-6C (EPC Gen 2) and can be read by RFID readers. They are typically made from materials such as PVC, PPS, epoxy, ABS, double layer laminated polyimide film, polyester-cotton blends, and hot-melt adhesive.

One of the most advanced UHF RFID laundry tags available in the market is the HLT laundry tag. It is a 3x3x0.7mm cube with an integrated antenna and chip, and is made with 200 strands of stainless-steel fibers twisted into an antenna. A polyester cotton blended fabric sheet is stitched to the end of the antenna. The HLT tag can be activated from a reader antenna anywhere in a range of RF fields that is acceptable, resulting in a powerful amplifier. The UHF silicone laundry tag is another popular option for industrial laundry applications. It is designed to be washed and dried more than 300 times, making it ideal for tracking objects that are frequently exposed to wet conditions.

In summary, washable RFID tags are a new type of tag that can be washed without affecting their performance. These tags are designed to withstand harsh conditions such as high temperatures, water, and chemicals. They are ideal for tracking and managing laundry items in environments such as hospitals, hotels, and industrial laundries. There are different types of washable RFID tags available in the market, including LF, HF, and UHF frequency tags, and they comply with industry standards such as EM 4100 and ISO/IEC 18000-6C (EPC Gen 2).

What does RFID mean in laundry?

RFID stands for Radio Frequency Identification, and it is a technology used to identify and track objects through radio waves. In the context of laundry, RFID is used to identify and track laundry items such as linens, uniforms, and towels, among others. RFID in laundry can be a game-changer for businesses that need to manage large amounts of laundry items efficiently.

RFID laundry tags are small transponders that are attached to laundry items and can be read by RFID readers. These tags can be either passive or active, and they come in different shapes, sizes, and frequencies. Passive RFID tags do not have an internal power source, while active RFID tags have a battery that powers the tag. The choice of tag depends on the specific needs of the business.

RFID tags for laundry are typically made of materials that can withstand harsh laundry processes such as washing, drying, and ironing. Some common materials used for RFID tags for laundry include PVC, PPS, epoxy, ABS, double layer laminated polyimide film, 65% polyester, 35% cotton, and hot-melt adhesive. These materials are chosen for their durability and resistance to water and chemicals.

Washable RFID tags are a new type of tag that can be washed without affecting the tag’s performance. These tags are made with a special material that is resistant to water and chemicals, making them ideal for use in environments where they may be exposed to harsh conditions. Washable RFID tags are also more durable than traditional tags, making them less likely to be damaged or destroyed.

RFID in laundry can be beneficial for businesses in several ways. First, it can help businesses keep track of their laundry items more efficiently. With RFID tags, businesses can monitor the location of their laundry items and know when items are checked in or out. This can help reduce the number of lost or misplaced items, which can save businesses time and money.

Second, RFID in laundry can help businesses improve their inventory management. With RFID tags, businesses can monitor the status of their laundry items and know when items need to be replenished. This can help businesses avoid stockouts and ensure that they always have enough laundry items on hand.

Third, RFID in laundry can help businesses improve their laundry processes. With RFID tags, businesses can monitor the performance of their laundry machines and know when machines need to be serviced or replaced. This can help businesses avoid downtime and ensure that their laundry processes run smoothly.

In addition to these benefits, RFID in laundry can also help businesses improve their customer service. With RFID tags, businesses can provide their customers with accurate and timely information about the status of their laundry items. This can help businesses build trust and loyalty with their customers.

Overall, RFID in laundry is a powerful tool that can help businesses manage their laundry items more efficiently. Whether it’s improving inventory management, reducing lost or misplaced items, or improving customer service, RFID in laundry can provide businesses with a competitive advantage. As the technology continues to evolve, we can expect to see even more innovative uses of RFID in laundry in the future.

Are RFID tags used on clothes?

Yes, RFID tags are commonly used on clothes. In fact, the use of RFID technology in the garment industry has been growing rapidly in recent years. RFID tags are small, computer-readable transponders that are embedded in clothing or other objects and are used to track and manage inventory, as well as to improve the overall supply chain management process.

RFID tags for clothes are typically made from materials that are resistant to water, chemicals, and high temperatures so that they can withstand the washing, drying, and ironing processes that clothes go through. These tags are also designed to be discreet and to not interfere with the appearance or feel of the garment.

There are several benefits to using RFID tags on clothes. One of the main advantages is that they can help to reduce the amount of time and labor required to track and manage inventory. By using RFID tags, companies can quickly and easily locate specific items of clothing and track them as they move through the supply chain, from production to distribution to retail.

Another benefit of using RFID tags on clothes is that they can help to prevent theft and reduce losses due to misplaced or stolen items. RFID tags can be used to monitor the movement of clothes within a store, which can help to identify areas where theft is more likely to occur. This information can then be used to improve store security and prevent future losses.

In addition to these benefits, RFID tags on clothes can also help to improve customer experience. For example, retailers can use RFID technology to track the availability of specific items of clothing and ensure that they are always in stock. This can help to reduce wait times for customers and improve overall customer satisfaction.

Overall, RFID tags are a valuable tool for managing and tracking inventory in the garment industry. They offer a range of benefits, including improved efficiency, reduced losses, and enhanced customer experience. As the use of RFID technology continues to grow, it is likely that we will see even more innovative applications of this technology in the garment industry and beyond.

What is the use of RFID in washing machine?

RFID technology has revolutionized the laundry and textile industries by providing a more efficient and accurate way to track and manage the movement of laundry items. One of the key uses of RFID in washing machines is to automate the identification and sorting of laundry items based on their RFID tags.

When RFID tags are attached to laundry items, such as towels, sheets, and clothing, they can be read by RFID readers installed in washing machines. As the laundry items are loaded into the machine, the RFID reader identifies each item and sends the data to the washing machine’s control system. This allows the machine to automatically select the appropriate wash cycle and temperature settings for each item, ensuring that they are washed according to their specific requirements.

In addition to automating the washing process, RFID technology can also be used to track the movement of laundry items throughout the laundry facility. By installing RFID readers at key points in the laundry process, such as at the entry and exit points of washing machines and dryers, laundry managers can track the movement of individual items and monitor their progress through the laundry process.

This allows laundry managers to identify bottlenecks in the process and optimize their operations for maximum efficiency. For example, if a particular washing machine is frequently overloaded with laundry items, RFID data can help managers identify the problem and take steps to address it, such as by adding additional machines or adjusting their staffing levels.

Another key use of RFID in washing machines is to prevent loss or theft of laundry items. By attaching RFID tags to each item, laundry managers can monitor their location and ensure that they are returned to the correct location after washing. This can help prevent the loss of valuable items, such as hotel linens or uniforms, and reduce the need for costly replacements.

Overall, the use of RFID in washing machines offers significant benefits for laundry managers, including increased efficiency, improved inventory management, and reduced loss or theft of laundry items. As RFID technology continues to evolve and become more widespread, it is likely that it will play an increasingly important role in the laundry and textile industries.