RFID on metal surface

RFID TAG MAKER is a professional and reliable supplier of RFID on metal surface for various applications and industries. We offer high-quality products at competitive prices and provide customized solutions to meet your specific needs. Contact us today to find out more about our products and services.

RFID TAG MAKER is a leading manufacturer of RFID on metal surface, which are designed to be attached to metal surfaces and objects. RFID on metal surface are ideal for tracking and managing metallic assets in various industries, such as manufacturing, logistics, healthcare, and automotive.

What are RFID on metal surface?

RFID on metal surface are RFID tags that can be mounted directly on metal surfaces or products. They are specially calibrated to work on metallic surfaces, which can interfere with the performance of regular RFID tags. RFID on metal surface are typically rugged, durable, and easy to attach by welding, screwing, or adhesive.

What are the benefits of RFID on metal surface?

RFID on metal surface offer many benefits for asset tracking and management, such as:

– High read range: RFID on metal surface can achieve a long read range of up to 100 meters, depending on the frequency and reader. This enables fast and accurate identification of metallic assets in large areas or warehouses.

– High reliability: RFID on metal surface are resistant to harsh environments, such as high temperature, moisture, dust, and vibration. They can withstand repeated use and wear and tear without losing functionality or data integrity.

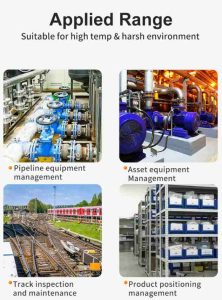

– High versatility: RFID on metal surface can be used for various applications and industries that involve metal surfaces or objects, such as metal tools, gas cylinders, vehicles, containers, machinery, etc. They can also be customized to fit different shapes, sizes, and requirements.

What are the types of RFID on metal surface?

RFID on metal surface can be classified into different types based on the frequency, shape, size, and features. Some of the common types are:

– High frequency (HF) RFID on metal surface: These tags operate at 13.56 MHz and have a short read range of up to 1 meter. They are suitable for applications that require close proximity or high security, such as access control or payment systems.

– Ultra-high frequency (UHF) RFID on metal surface: These tags operate at 860-960 MHz and have a long read range of up to 100 meters. They are suitable for applications that require fast and accurate identification of large numbers of metallic assets, such as inventory management or logistics.

– Active RFID on metal surface: These tags have a battery that powers the tag and enables it to transmit a signal periodically or on demand. They have a longer read range and battery life than passive tags, but they are also more expensive and bulky. They are suitable for applications that require real-time location or status monitoring of metallic assets, such as asset tracking or security systems.

– Passive RFID on metal surface: These tags do not have a battery and rely on the reader’s signal to power the tag and transmit data. They have a shorter read range and battery life than active tags, but they are also cheaper and smaller. They are suitable for applications that require low-cost and low-maintenance identification of metallic assets, such as asset tagging or work-in-process.

What are some examples of RFID on metal surface?

Some examples of RFID on metal surface that RFID TAG MAKER produces are:

– Metal tool tags: These are small and durable UHF RFID on metal surface that can be attached to metal tools or equipment. They can be used for tool tracking, inventory management, maintenance records, etc.

– Metallic surface labels: These are flexible and adhesive UHF RFID on metal surface that can be applied to any metallic surface. They can be used for product identification, quality control, warranty verification, etc.

– RFID metal stickers: These are thin and discreet HF RFID on metal surface that can be adhered to any metal object. They can be used for access control, payment systems, loyalty programs, etc.

– Metal mount transponders: These are active 2.45 GHz RFID on metal surface that can be mounted on any metal surface or product. They can be used for real-time location tracking, status monitoring, theft prevention, etc.

RFID on metal surface specifications :

Mechanical Specifications:

Material: PCB

Size: Customize size

Weight: 36g/1.27OZ

RF Specifications:

Frequency: 866-868MHz、902-928MHz

Protocol: ISO 18000-6C

Reading range: Up to 3m

Chipset: Alien H3

Memory: 96 bit EPC, 512-bit User Memory

Environment Specifications:

Operation temp: -40 – 85℃

Store temp: -40 – 250℃

Protection: IP68

Mounting way: Screw, rivet, epoxy

Certification: Meet CE requirement

Warranty: 12 months after delivery

Lifecycle: More than 10 years