RFID PCB tag

we are a leading manufacturer of RFID PCB tags in China. We have more than 15 years of experience in producing high-quality and reliable RFID products for various applications. We offer a variety of RFID PCB tags with different sizes, shapes, frequencies, memory capacities, and features. We can also customize our products according to your specific needs and preferences.

Introducing RFID PCB Tag: A Smart Solution for Asset Tracking

RFID (Radio Frequency Identification) is a technology that uses radio waves to identify and track objects. RFID tags are small devices that store information and can be attached to various items, such as products, tools, equipment, vehicles, etc. RFID readers are devices that can read the information stored in the tags and communicate with a computer system.

RFID tags can be classified into different types according to their power source, frequency, memory capacity, and application. One of the most common and versatile types of RFID tags is the RFID PCB (Printed Circuit Board) tag. This RFID PCB tag consists of a PCB with an antenna and a chip embedded on it. The PCB provides a rigid and durable structure for the tag, as well as a platform for mounting other components or sensors.

RFID PCB tags have many advantages over other types of RFID tags, such as:

– High performance: RFID PCB tags can provide excellent read range and data transfer speed, especially when mounted on metal surfaces. They can also operate in harsh environments, such as high temperature, humidity, vibration, and impact.

– Low cost: RFID PCB tags can be mass-produced using standard PCB manufacturing processes, which reduces the production cost and time. They can also be customized according to different specifications and requirements.

– Easy integration: RFID PCB tags can be easily integrated with other electronic devices or systems, such as Bluetooth speakers, headphones, medical devices, etc. They can also be encapsulated in special labels or covers for different applications.

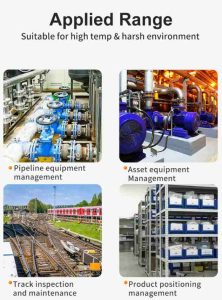

RFID PCB tags have a wide range of applications in various industries, such as:

– Asset tracking: RFID PCB tags can be used to track and manage assets, such as tools, equipment, vehicles, etc. They can provide real-time information about the location, status, usage, and maintenance of the assets. They can also prevent theft, loss, or misuse of the assets.

– Medical device authentication: RFID PCB tags can be used to authenticate medical devices, such as cartridges, syringes, implants, etc. They can ensure that the devices are genuine, compatible, and safe to use. They can also store relevant information about the devices, such as expiration date, dosage, etc.

– PCB management: RFID PCB tags can be used to manage PCBs during the manufacturing process. They can store information about the PCBs, such as model number, serial number, production date, etc. They can also enable automatic identification and quality control of the PCBs.

We are a leading manufacturer of RFID PCB tags in China. We have more than 15 years of experience in producing high-quality and reliable RFID products for various applications. We offer a variety of RFID PCB tags with different sizes, shapes, frequencies, memory capacities, and features. We can also customize our products according to your specific needs and preferences.

Our RFID PCB tags are compliant with international standards and certifications, such as ISO 14443A/B/C/D/E/F/G/H/I/J/K/L/M/N/O/P/Q/R/S/T/U/V/W/X/Y/Z/AA/AB/AC/AD/AE/AF/AG/AH/AI/AJ/AK/AL/AM/AN/AO/AP/AQ/AR/AS/AT/AU/AV/AW/AX/AY/AZ/BA/BB/BC/BD/BE/BF/BG/BH/BI/BJ/BK/BL/BM/BN/BO/BP/BQ/BR/BS/BT/BU/BV/BW/BX/BY/BZ/CA/CB/CC/, EPC Gen2 Class 1/C1G2/C2G2/C3G2/C4G2/C5G2/C6G2/C7G2/C8G2/C9G2/C10G2/C11G2/C12G2/C13G2/C14G2/C15G2/C16G2/, ISO 15693/I-CODE SLI/I-CODE SLIX/I-CODE SLIX-S/I-CODE SLIX-L/I-CODE SLIX-2/, ISO 18000-6C/UHF Gen 2/UHF C1G2/UHF C2G2/UHF C3G2/UHF C4G2/UHF C5G2/UHF C6G2/UHF C7G2/UHF C8G2/UHF C9

How to custom RFID PCB tags

The manufacturing process of RFID PCB tags involves the following steps:

– Designing the antenna and the chip: The antenna and the chip are the main components of an RFID PCB tag. The antenna is responsible for receiving and transmitting radio signals, while the chip is responsible for storing and processing data. The design of the antenna and the chip depends on the frequency, performance, size, and shape of the tag. The antenna can be printed on the PCB using conductive ink or etched using copper foil. The chip can be either embedded in the PCB or attached to it using a flip-chip or wire-bonding technique.

– Fabricating the PCB: The PCB is the substrate that supports the antenna and the chip. The PCB can be made of various materials, such as FR4, PET, PI, etc. The fabrication of the PCB involves cutting, drilling, plating, laminating, and testing processes. The PCB can be customized according to different specifications and requirements.

– Mounting the components: The components are mounted on the PCB using solder paste or conductive adhesive. The components include the antenna, the chip, and any other sensors or devices that are integrated with the tag. The mounting process can be done manually or automatically using pick-and-place machines.

– Encapsulating the tag: The tag is encapsulated in a protective cover or label to prevent damage from environmental factors, such as moisture, dust, heat, etc. The encapsulation can be done using various methods, such as injection molding, over-molding, over-spraying, etc. The encapsulation can also provide aesthetic and functional features for the tag.

The manufacturing process of RFID PCB tags can be mass-produced using standard PCB manufacturing processes, which reduces the production cost and time. It can also be customized according to different applications and needs.

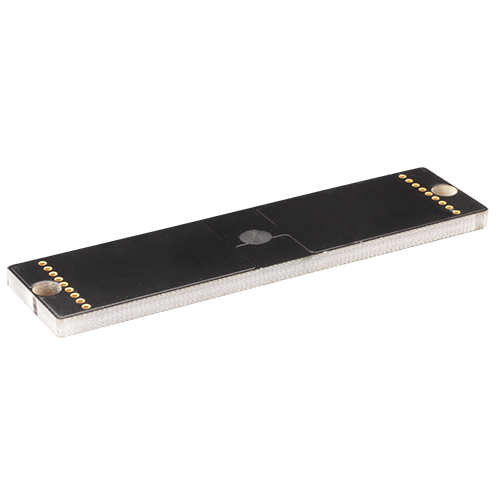

RFID PCB Tag specifications :

Mechanical Specifications:

Material: PCB

Size: Customize size 70*20mm or custom any size

Weight: 36g/1.27OZ

RF Specifications:

Frequency: 866-868MHz、902-928MHz

Protocol: ISO 18000-6C

Reading range: Up to 3m

Chipset: Alien H3

Memory: 96 bit EPC, 512-bit User Memory

Environment Specifications:

Operation temp: -40 – 85℃

Store temp: -40 – 250℃

Protection: IP68

Shock and vibration: MIL STD 810-G

Mounting way: Screw, rivet, epoxy

Certification: Meet CE requirement

Warranty: 12 months after delivery

Lifecycle: More than 10 years