RFID tire tags

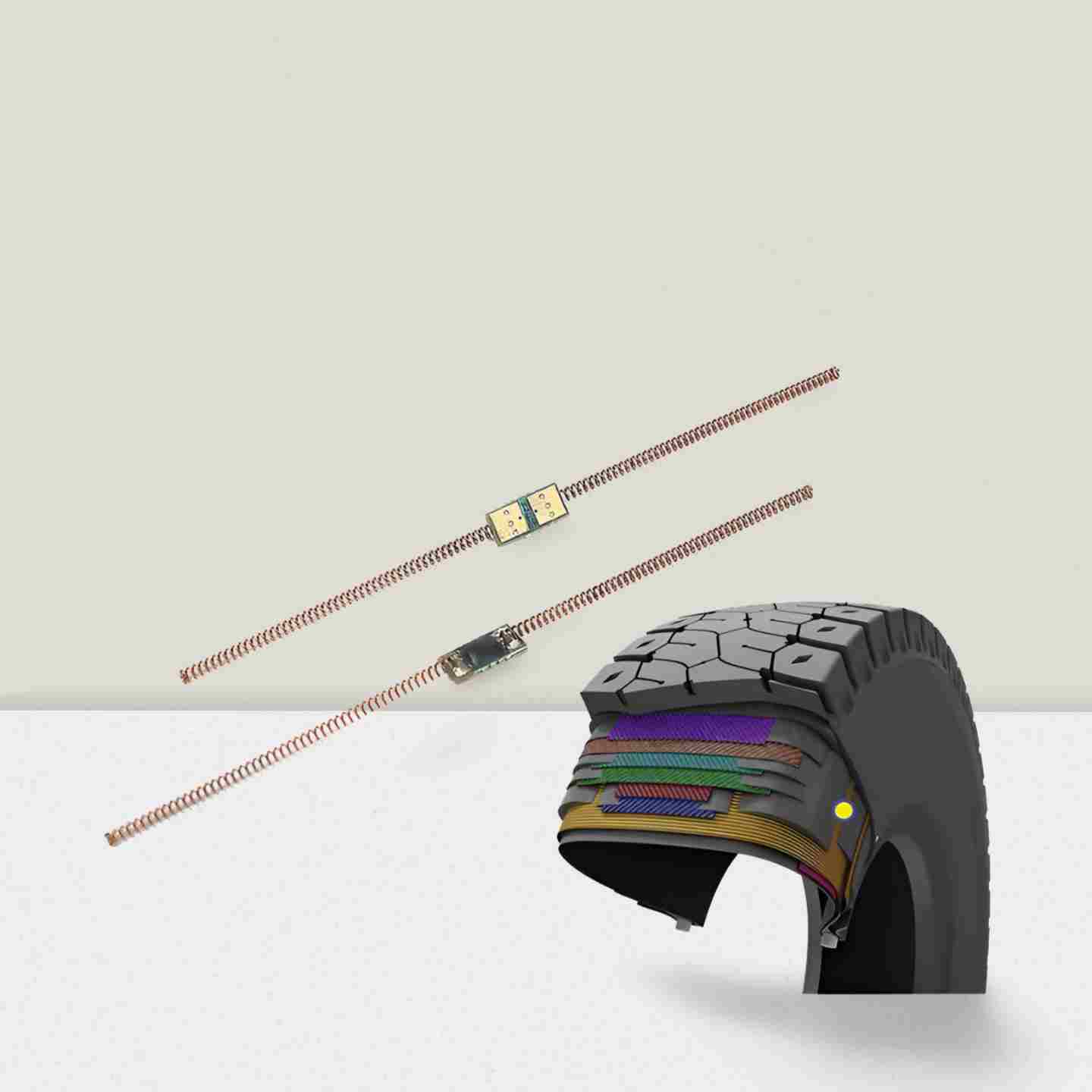

The RFID tire tag is a small, robust device embedded into automobile tires. It uses Radio Frequency Identification (RFID) technology to store and transmit data. This data can be accessed remotely, providing real-time information about each tire’s status and history.

Revolutionizing the Tire Industry with RFID Tag Maker’s RFID Tire Tag

In the rapidly evolving world of technology, RFID Tag Maker is leading the charge with its innovative product, the RFID tire tag. This groundbreaking technology is set to redefine the tire industry, offering unprecedented levels of efficiency and data management.

RFID Tags in Tires: A Game Changer

The RFID tire tag is a small, robust device embedded into automobile tires. It uses Radio Frequency Identification (RFID) technology to store and transmit data. This data can be accessed remotely, providing real-time information about each tire’s status and history.

The Power of RFID Tire Tag

The RFID tire tag is more than just a tracking device. It’s a tool that can transform every aspect of the tire industry. From manufacturing and distribution to sales and repairs, the RFID tire tag offers a range of benefits:

Logistics and Inventory Management: The RFID tire tag significantly reduces the workload required for inspecting incoming and outgoing tire shipments, and for taking inventory of tires.

Automobile Production Line: The RFID tire tag prevents new cars from having an improper mix of incoming tires or from having such tires mounted in the wrong position.

Vehicle Tire Check: The RFID tire tag allows for checking the tire air pressure and tread depth remaining in a paperless manner, lightening the workload for on-site workers.

Retread: Tire product information necessary for tire retreading can be obtained from RFID tags, and retreading applications can be recorded without fail.

Checking of Tires to be Disposed of: The RFID tire tag helps to efficiently keep track of any potential scrap tires while marking them as retreading, recycling, disposal, etc., and encourages them to be reused in an environmentally sound way.

Embracing Industry Standards

RFID Tag Maker’s tire-embeddable RFID tags are encoded with an SGTIN-96 that functions as a tire ID, and tire product information is stored in a cloud database. The RFID communication standard recommended for tires is RAIN RFID operating at the UHF (860 MHz to 960 MHz) band, and the RFID data format used for tires is GS1 SGTIN-96.

With the RFID tire tag, RFID Tag Maker is not just changing the tire industry – it’s shaping the future. By embracing this technology, businesses can improve efficiency, reduce costs, and contribute to a more sustainable world.

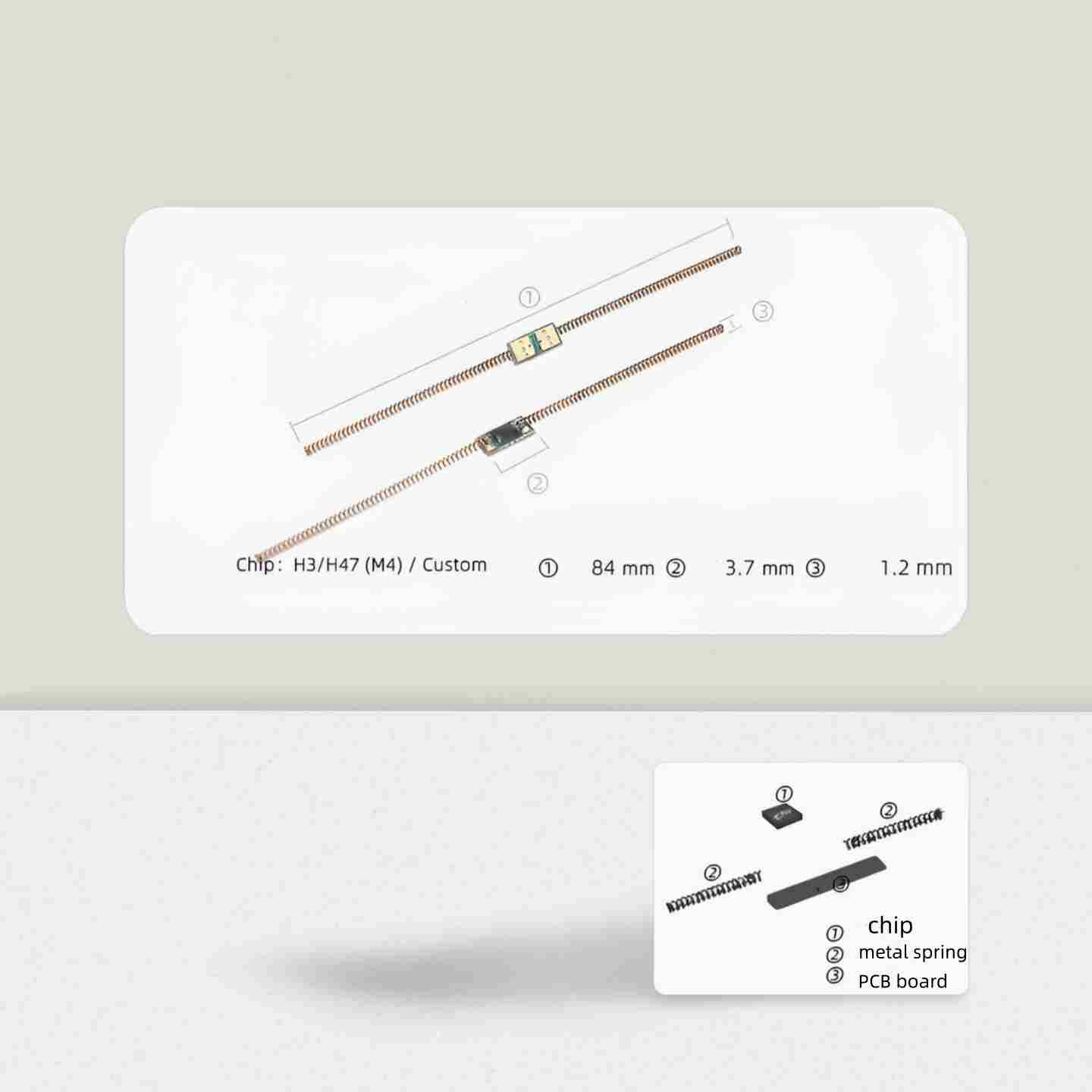

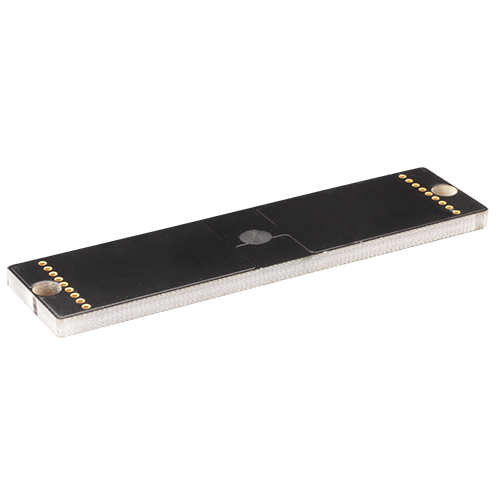

Physical Parameters:

– Total Length: 40mm-60mm (Tuning according to different tires)

– Width: 3.0mm – 3.5mm

– Thickness: 1.0mm – 1.5mm

– Weight: <0.2g – <0.16g

Specifications:

– Protocol: ISO18000-63/EPC class 1 generation 2/ ISO 2019: 20909

– EPC: Up than 96bits, support SGTIN-96 coding

– User Memory: 0bit, 512bit, 2k bit

– Privacy: Can lock and permanently lock

Performance Parameters:

– Reading Distance: >0.8m(TBR), >1.8m(PCR)

– Writing Distance: >50% of the reading distance

– Working Temperature: -40℃~85℃

– Survival Temperature: -45℃~125℃

– Resistant of Curing: Withstand the pressure up to 5MPa, the temperature up to 200℃ within tyre curing time

– Frequency: 860MHz-960MHz

– Data Retention: >20 years

– Write Cycle Endurance: >100,000 times

These RFID tire tags are designed to be robust and durable, capable of withstanding harsh conditions while providing reliable performance. They offer a range of benefits for the tire industry, including improved logistics and inventory management, enhanced quality control, and more efficient production processes. Please let me know if you need more information on this topic!