RFID tags for equipment

One of the key features of RFID Tags for Equipment is its flexibility, which allows it to be attached to any surface of the equipment. The tag’s surface can also be customized to display relevant information through printing, and its chip can be encoded to store additional data.

Description :

One of the key features of RFID Tags for Equipment is its flexibility, which allows it to be attached to any surface of the equipment. The tag’s surface can also be customized to display relevant information through printing, and its chip can be encoded to store additional data.

The RFID Tags for Equipment is especially useful in tracking IT assets, computers, and tablets. Its flexible design enables it to be easily attached to various surfaces of these devices, such as the back of a laptop screen or the side of a tablet. This ensures that the tag stays in place and is not easily lost or damaged.

In addition to its flexibility and ease of use, the RFID Tags for Equipment is also highly durable and reliable. It can withstand harsh environments and remain functional even after prolonged exposure to water, dust, and other elements.

RFID Tag Maker is committed to producing high-quality and reliable RFID tags that can be used for various applications. Their tags are manufactured using the latest technology and are tested rigorously to ensure their durability and reliability.

Why use RFID tags for equipment?

Efficient tracking: RFID Tags for Equipment allows for efficient tracking of various types of equipment. With its high read range and ability to store relevant data, the tags can help organizations quickly locate and manage equipment.

Cost-effective: Using RFID Tags for Equipment can be a cost-effective way to track and manage equipment. With the ability to reuse tags and the efficiency of tracking, organizations can reduce costs associated with lost, stolen or misplaced equipment.

Accurate data: RFID Tags for Equipment can provide accurate data that is necessary for inventory management, maintenance, and other activities. The tags can store important information such as the equipment’s location, status, and maintenance history, making it easy to track and manage.

Time-saving: RFID Tags for Equipment can save time by allowing organizations to quickly locate and manage equipment. This can help to increase productivity and efficiency.

Durability: RFID Tags for Equipment are durable and can withstand harsh environments, making them suitable for use in various industries.

RFID tags for equipment Features:

High-performance reading range

Available in high-yield volume with stable process

Compliant with RoHS

Humidity environment: suitable for indoor and outdoor uses

Dirt, dust and water-resistant

Programming and encoding: provide services which exactly fit customers’ programming or encoding requirements

RFID tags for equipment Specification:

| Air Interface Protocol | EPC Class 1 Gen 2 (ISO 18000-6C) |

| Tag Form Factor | Label Tag |

| Tag Materials | Printable White PET |

| Applicable Surface Materials | Plastic and non-metallic substrates |

| Attachment Method | General Permanent Adhesive |

| IC Type | lmpinj Moza R6-P |

| Weight | 0.001 lbs. (0.50 g) |

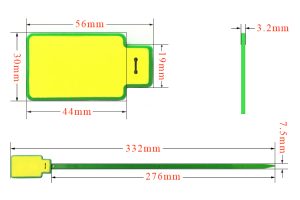

| Dimensions | 60 × 25 × 0.8 mm |

| IP Rating | IP67 |

| Operating Frequency | 860 – 960 MHz (Global) |

| Maximum Read Distance | Fixed Reader: Up to 9.8 ft. (3 m)

Handheld Reader: Up to 8.2 ft. (2.5 m) |

| Operating Temperature | -40 °F to 185 °F (-35 °C to 85 °C) |

| Storage Temperature | -40 °F to 446 °F (-35 °C to 85 °C) |

| Memory | EPC: 128/96 bits*

User: 32/64 bits* TID: 96 bits *Reprogrammable memory |

| Compatible Printers | Sato’s CL4NXZebra’s ZT4 10 R110Xi4

Posteck’s TXr |