Unleashing the Power of RFID Tire Tags: A Revolution in the Automotive Industry

Introduction

Radio Frequency Identification (RFID) is a transformative technology that has found its way into various industries, including the automotive sector. One of the most innovative applications of RFID in this field is the integration of RFID tags into tires, a development that promises to revolutionize tire management and safety.

How RFID Tire Tags Work

RFID tire tags are passive electronic chips that exchange data with a reader using radio frequency signals. These tags, embedded into tires, ensure reliable identification of each tire and form the basis for data-driven services and solutions, a key pillar of connected mobility.

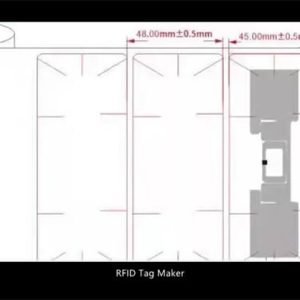

The RFID tire tag comprises three main components: hardware, an identifier, and a cloud database. The hardware includes a chip set and an additional antenna, protected by two rubber layers and embedded into the tire or added as a patch during post-manufacturing. The identifier is a unique item identifier that follows the GS1 EPC global coding scheme, ensuring authenticity. It contains information such as the company prefix, item reference, and serial number. The cloud database manages the data associated with each tire ID.

Applications of RFID Tire Tags

RFID tire tags have a wide range of applications:

Logistics and Inventory Management: RFID tags significantly reduce the workload required to check incoming and outgoing goods and to inventory tires. They enable suppliers to track inventory and warehouse more effectively.

Automobile Production Line: RFID technology can improve and ensure the assembly process of tires and wheels.

Tire/Wheel Combination: RFID technology can improve and ensure the assembly process of tires and wheels.

Vehicle Tire Inspection: RFID technology can make vehicle tire inspection quick and efficient.

Refurbished Tires: RFID tags can give tires a second life. RFID ensures efficiency and traceability during the refurbishment process.

Handling End-of-Life Tires: RFID technology can inspect end-of-life tires.

Advantages of RFID Tire Tags

RFID tire tags offer several advantages:

Increased Efficiency: RFID tags streamline processes, from manufacturing to logistics, thereby increasing overall efficiency.

Enhanced Safety: By providing real-time data on tire conditions, RFID tags contribute to road safety.

Traceability: RFID tags ensure the traceability of each tire, which is crucial for quality control and recall management.

Future Applications of RFID Tire Tags

RFID technology will be used to monitor the entire process of tire production to delivery, providing a “significant contribution” to regular predictive maintenance. Furthermore, it can enhance driver safety by allowing advanced driver assistance systems, such as ESP, to obtain an effective response to specific tire requirements.

The integration of RFID tags into tires is not just a revolution in the tire itself but also leads to changes in tire manufacturing technology and production equipment. As we move towards a more connected and data-driven world, the importance of technologies like RFID tire tags cannot be overstated.